And so, I was figuring out a way to make your own twisted wire after the silversmithing class. Even before the class, I've already came across in a magazine with pictorial illustration on how it is done. It was exactly like how I did it in the silversmithing class.

The problem was of course in getting one end of the wires clamp down. Bench clamp/pin does seem to be the best option but c'mmon, there has got to be an alternative! I sure ain't gonna buy myself a bench pin, let alone a bench clamp! I mean, all I wanted to do is to twist wires. That's it. What else would I need either one of it for?

I came across this article by Dale Armstrong from wire-sculpture.com which talks about twisted wires. It's quite a long article, but if you're too lazy to read it, I'll summarize it for you here. It mainly talks about the different tools that can be used to create twisted wires, how to use them and her opinion on each an every one of it with bits of tips on twisted wire.

When I was going through the tools recommendation, I pretty much just skim through it. I mean, bench clamp/pin is giving me enough headache already and here, you have tools like wire-twisting pliers, cordless power screwdriver, keyless head chuck and what have you! Spare me, please ..... -_-

There has got to be a simpler way.

When it comes to tools, I can be both a specialist and a minimalist. I appreciate tools with specialized function but would also like to keep it to a minimal at the same time. Point is, all the above doesn't quite fit into my criteria, although a bench pin would have been close but for the fact that I don't think I'll be sawing through metal sheet anymore lor! :P

So, this is how I eventually found a way to do it. Somewhat primal in nature but fool-proof! And most importantly, I get what I want! :P

Nothing fancy. Just by using stuffs that you already have.

This is all that you need.

A chain nose pliers, a pencil and wires. Here, I use 0.6mm or approximately 22ga wire.

Ouh.... one more thing......

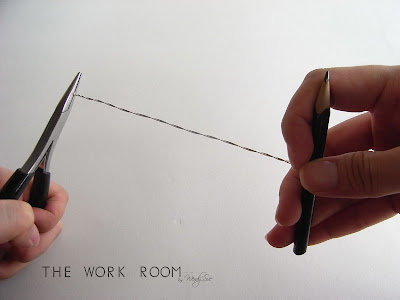

Cutters to cut the wires of course! Heheh.... :)

Now, grip both ends of the wires with your chain nose pliers.

Okay, here, I'll digress a little to talk about the jaws of the pliers. It may be a digression but very relevant nonetheless.

If you have ever noticed, this is how the pliers actually grips.

I'm not sure if the picture above come across clear enough but if you could, you might notice that there is only the wire on the left has maximum contact with the jaw but there is some sort of gap between the wire on the right and the jaw. In other words, the jaw seems only to grip onto the wire on the left and the wire on the right tends to slip away. It's not noticeable at all when there's only one wire in action but when you've got two like the case here, this becomes very apparent. You'll probably have difficulty gripping the two since one will tend to slip away every now and then.

This has much to do with the way the pliers actually grips. Observe the illustration below.

Picture courtesy of www.votawtool.com

The illustration on the left shows you how the pliers actually grip. The illustration on the right shows you how parallel action pliers grip. Comparing the two, it's pretty obvious that parallel action pliers offer maximum contact between jaws and this highly improves gripping power.

Everyone, meet flat parallel action pliers.

This plier is described as having the cross section of both jaw ends flat. This means that the jaw has a flat area that is the same width all the way to the tip of the jaws.

I think this type of pliers is more common in the realm of silversmithing. Well, I reckon it to be so because that was where I was introduced to it la.

Anyway, not exactly an essential tool but a rather smart one. One which you can do without but I guess wouldn't mind having IF you'ce got THAT much of an extra cash to spare! LOL...... This pliers certainly do not come cheap nor economical. This is going to set you back for around £20! Essential or luxury?

You tell me......

Riiiight, back to where we were.

As I was saying, grip both wire ends with your pliers. I still think you can grip the two together. You just probably need to play around with the position a little to finally find one which works for you. I personally find that the grip seems to do okay at the tip but you might find it working well for you at the end. Either way, just play around a little.

The article also suggested the use of flat nose plier instead of chain nose on the premise of longer surface area of chain nose but I dont quite see the difference really, since the two still grip the same way. *shrugs* Haven't got a flat nose now for me to try them out. Used to have an economical version one but I think it got lost in transition when we moved to this new house since I wasn't around to do the packing. o_O

Either way, as the wires starts to intertwine to become one, it will be much easier for you to grip the ends already since the two has become one.

Anyway.......as I was saying.......

Then, slide your pencil through the loop on the other end.

Talking about pencil, the longer it is, the better it is because the longer it is, the better control you have.

Next, comes the twisting part. This is how I'm suggesting it to you.

Hold your wire vertically like this.

And start turning the pencil either clockwise or anti-clockwise. Remember that you must only turn in the same direction throughout.

This is my rationale for holding it vertically instead of ......

This is my rationale for holding it vertically instead of ......

horizontally, simulating what I did in the silversmithing class.

This is what I think.

The tension is important here in creating evenly twisted wires. You simply can't compare the consistency of tension when using our hands as compared to with the help of bench clamp/pin. That is why I suggested the pencil end backed by a flat surface on the floor for support. Bear in mind that you will need to pull both ends of wires taut while twisting at the same time.

I find this position works best for me but you can also try it horizontally if you want but I do suggest some kind of support on the twisting end. Twisting it in the air without support might be too strenous. Nevertheless, I think it is still possible very shorter wire lengths.

Eventually, you'll see both the wires starting to intertwined with each other.

Keep on twisting untill you've reached the 'tightness' that you want. However, bear in mind to not twist them too tight ot you risk breaking the wires.

This is what I think.

The tension is important here in creating evenly twisted wires. You simply can't compare the consistency of tension when using our hands as compared to with the help of bench clamp/pin. That is why I suggested the pencil end backed by a flat surface on the floor for support. Bear in mind that you will need to pull both ends of wires taut while twisting at the same time.

I find this position works best for me but you can also try it horizontally if you want but I do suggest some kind of support on the twisting end. Twisting it in the air without support might be too strenous. Nevertheless, I think it is still possible very shorter wire lengths.

Eventually, you'll see both the wires starting to intertwined with each other.

Keep on twisting untill you've reached the 'tightness' that you want. However, bear in mind to not twist them too tight ot you risk breaking the wires.

You might also notice something here. You might notice that the wires twist tighter on both ends which seems to be a common scenario given the inconsistency in tension.

But which is quite okay, really because the centre does appear evenly twisted.

Because then, this is what you can do to get what you want.

Just.........

Snip both the ugly ends off.....

To get what you want lor! LOL...... XD

A nice piece of twisted wire! =)

Okay, here's the thing. This method may be fool proof but I didn't say that it is possibly potentially a fool's method. :P

Let's face it. This method can only work for short pieces of twisted wire. If you want longer pieces of wire, this might be a fool's method after all, for the simple reason that from a long piece of wire's context it's not exactly a very practical method. But hey, it works, okay! :P

For one, it's going to be VERY time consuming and secondly, the risk of the 'death grip'! You know how sometimes you grip so hard on the pliers like your life depends on it? Yeah, THAT's a death grip.

So, I would think this will work alright if you do not want to spend on tools and merely wanted to add a surprise element to your work. Maybe not for a piece which screams, "Hey, look! I'm all twisted!" but rather more for a piece that would probably say, "Hey, look over here.. I'm a 'lil twisted here...;)"

Know what I mean? Maybe to create something like connectors or clasp or even eye or head pin if you can pass it through the bead.

Exactly how far is the length that you can go is rather subjective. I think it should be a length short of causing you spasm; arm, wrist, fingers or otherwise! LOL.... no, seriously. The 'death grip' is no joke in the long run, I kid you not.

If you do want to do this for real, the I think it's probably best you consider investing in a tool to help you with. If you're just like me who just wants a little of it here and there to pump up the fun factor, this will work out just fine.

Only two things to keep in mind:

- Twisting of wire will harden it. A point you may want to consider when using lower gauges wire.

- The more tightly the wires are twisted, the more prone it is to breakage because the wire becomes thinner and weaker. A point you may want to consider in the design department especially if it's going to involve a lot of folding.

.jpg)

0 hollers:

Post a Comment